ARIBOT: Autonomous Railway Inspection Platform

ARIBOT automates railway track inspection by combining ROS-driven autonomy, multi-modal sensing, and cloud analytics, delivering continuous defect detection for ballast, rails, sleepers, and fasteners.

Objective

Contributed to an autonomous inspection robot that addresses the safety, labor, and accuracy gaps in manual railway maintenance across India. The platform executes ultrasonic NDT, 3D laser profiling, and visual anomaly detection to surface actionable insights for maintenance crews.

Technology Stack

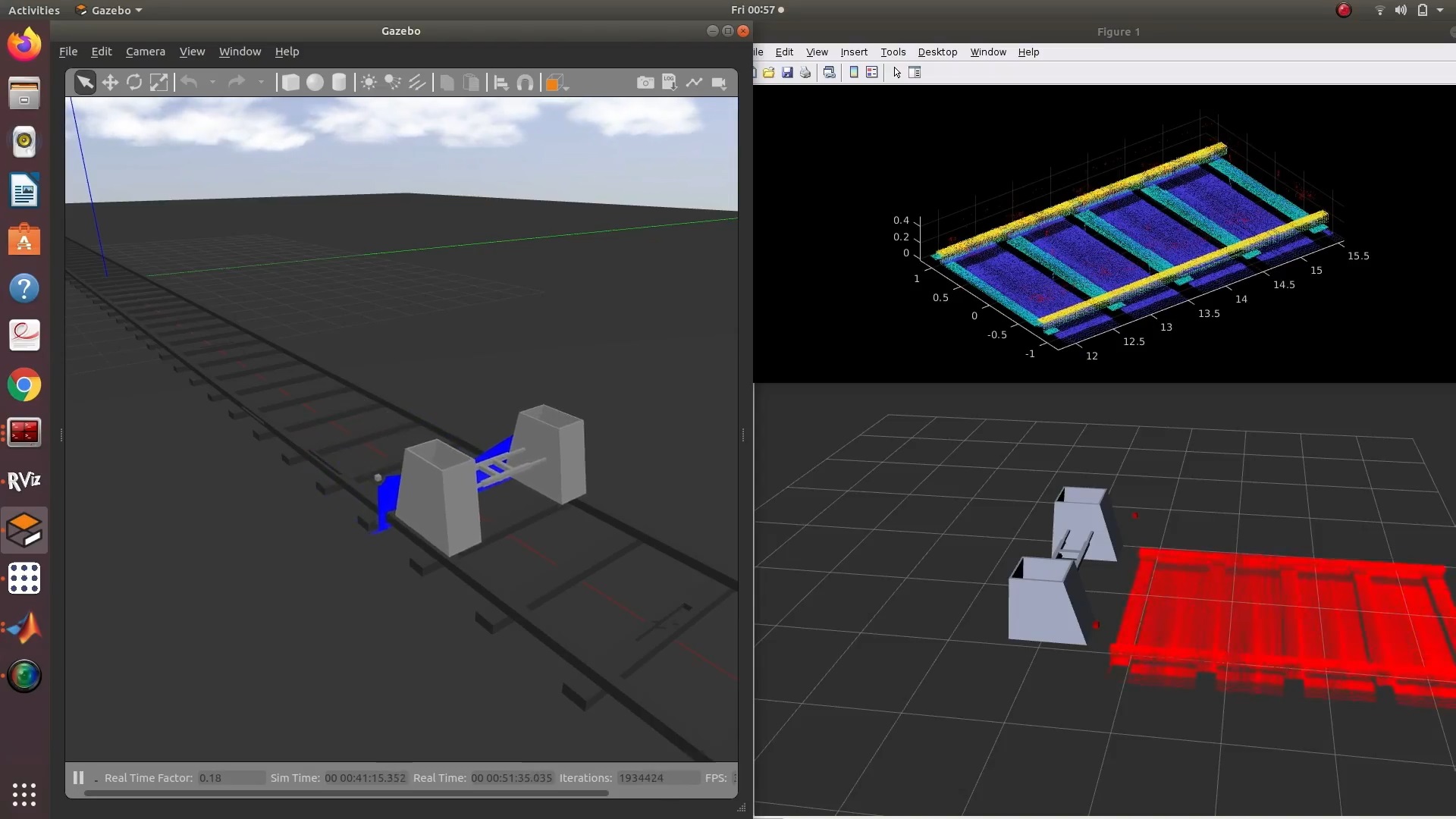

- ROS and Gazebo for autonomy, simulation, and digital twin validation.

- MATLAB analytics for post-processing inspection point clouds.

- TensorFlow-powered machine vision for fastener and sleeper anomaly detection.

- Integrated IMU, GPS, and laser scanners for precise localization.

- NGINX-served web dashboard for live telemetry and inspection playback.

Key Features

- Performs simultaneous ultrasonic and laser-based crack detection while on the move.

- Streams real-time inspection status, imagery, and defect logs to a responsive web interface.

- Autonomous navigation and positioning enable continuous coverage with minimal human oversight.

- Automated alerts encapsulate spatial coordinates and defect metadata for rapid intervention.

- Designed with modular hardware for quick sensor upgrades and field maintainability.

Outcome

The system demonstrates how robotics, machine vision, and predictive maintenance tooling can modernize railway inspection workflows, reducing manual effort while increasing the fidelity and frequency of safety checks.