Machine Vision Optimisation for Automotive Test Benches

Developed a cost-effective machine vision pipeline to automate throttle position sensor validation, improving repeatability, operator safety, and inspection throughput on high-cycle endurance rigs.

Objective

Benchmarked legacy end-of-line setups and designed a fiducial marker-based measurement flow that replaces manual inspection, allowing long-duration component tests to run autonomously with reliable data capture.

Methodology

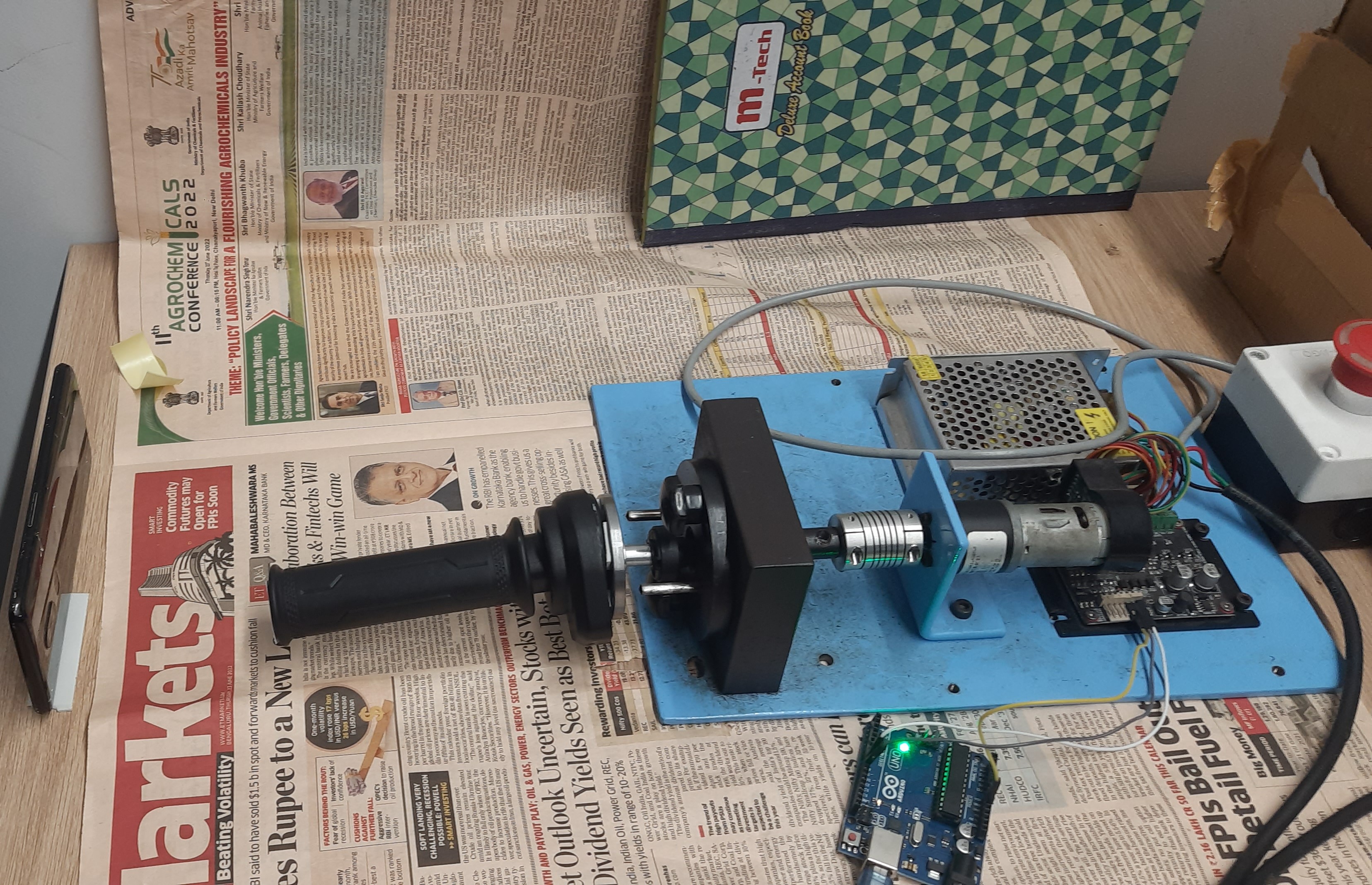

The solution ingests continuous video streams from a monocular camera, tracks fiducial markers on throttle actuators, and computes position deltas to validate sensor behavior under load. Control inputs are swept via low-cost motor actuators, while automated scripts flag out-of-tolerance responses for operator review.

Technology Stack

- OpenCV pipelines for marker detection and pixel-to-angle calibration.

- Custom fiducial markers to support camera resectioning and drift compensation.

- Python services orchestrating acquisition, analytics, and result logging.

- Cost-effective monocular camera, motor actuators without encoders, and compact power electronics.

Key Features

- Automates throttle position sensor validation for endurance testing campaigns.

- Delivers consistent measurements by pairing fiducial tracking with drift compensation.

- Flags out-of-tolerance responses in real time to accelerate technician triage.

- Packaged for rapid deployment on additional automotive component test rigs.

Outcome

Demonstrated reliable, automated TPS validation that reduces technician involvement, improves product quality, and establishes a template for extending vision-based diagnostics to additional automotive components.