Predictive Analytics for Structural Health Monitoring

Thesis work centered on continuous monitoring of shafts and bearings in heavy machinery, pairing vibration-based sensing with machine learning models to detect faults before failure.

Project Overview

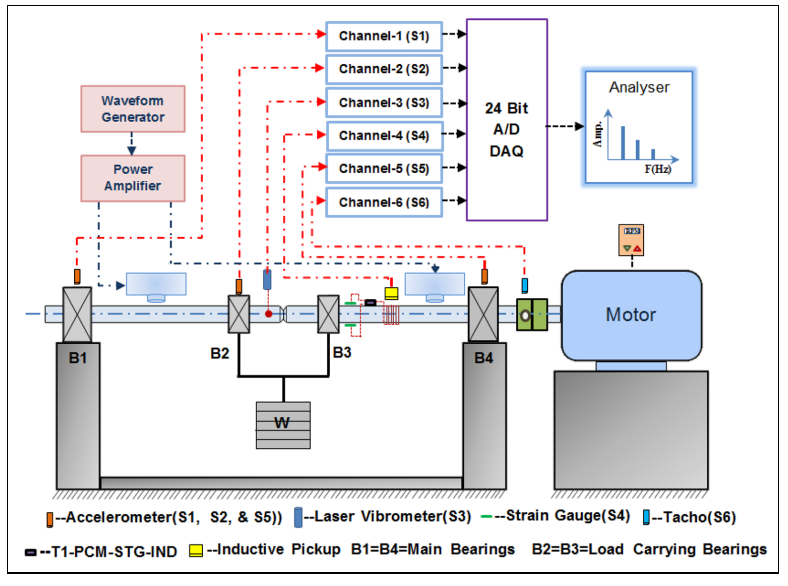

Designed end-to-end analytics that ingest real-time vibration data from industrial test benches, extracting features to predict the onset of component degradation and avert catastrophic failures in turbines and similar assets.

Methodology

Implemented time-series preprocessing, feature engineering, and LSTM networks to capture temporal signatures of component wear. Compared algorithmic predictions with ground truth events to confirm early warning capability and robustness across operating regimes.

Technology Stack

- Python-based data pipelines ingesting high-frequency vibration telemetry.

- LSTM architectures for temporal fault prediction in rotating machinery.

- PCA and related dimensionality reduction techniques for single-fault isolation.

- Clustering algorithms to separate multiple simultaneous bearing defects.

Key Features

- Benchmarked diverse machine learning models for rotor crack and bearing fault detection.

- Validated diagnostic workflows against experimental datasets from industrial-grade rigs.

- Quantified early warning capability by aligning predictions with observed fault events.

- Established a reusable analytics framework for large machinery health monitoring.

Conclusion

The research demonstrated strong agreement between algorithmic forecasts and experimental observations, illustrating how data-driven monitoring can transform maintenance strategies for large-scale rotating machinery.